1. PRE-SALE SERVICES

- Suggestions, Solutions for your application & requirements on voice call

- Site visit on demand. Payable basis.

- Analysing requirements based on the application.

- Selection of suitable pumps with right Material of construction (MOC) for the duty & site condition.

- Selection of fans for AH systems.

- Selecting equivalent fans for replacing/retro fitting imported/old fan.

- Complete protection & cooling solution for solar, Wind, UPS, Drives, BMS.

2. POST-SALES SERVICES

- Installation guide by professional service team for larger pumps on chargeable basis.

- Pre-commissioning; checking pipe lines and Electrical panel for larger pumps.

- Explaining procedures for operation & maintenance.

- Commissioning supervision for larger pumps.

- Visit & check pump and give report, by authorized service team

3. GENERAL SERVICES (CUSTOMER SERVICES)

- Services for out of warranty period pumps can be done on paid basis (for larger pumps only).

- Accessories available for engine sets: fuel tank, auto-panel, battery, lubricants oil for firefighting Engine sets.

- Mechanical seal fixing and servicing on chargeable basis.

- Pump set Alignments check and fixing on chargeable basis.

- Annual maintenance contract (AMC) for periodic checking health of pumping on chargeable basis.

SIMPLE INSTALLATION TIPS

LOCATION :

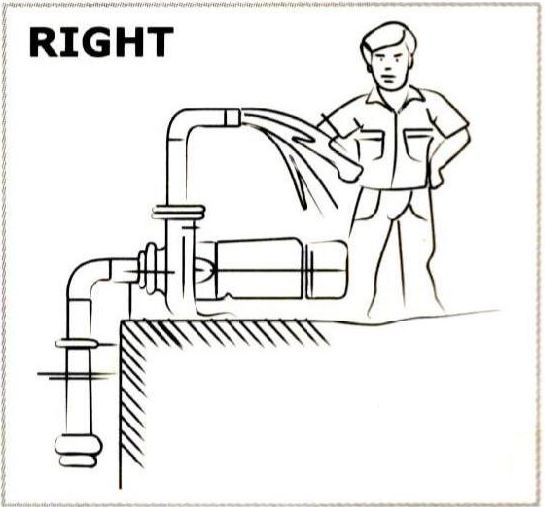

The Pump Should be Located Near to the water source to Minimize the suction Lift

GROUNDING :

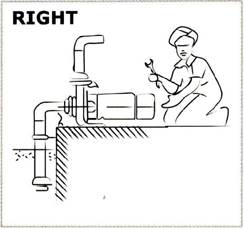

After Installation is completed, the foundation bolts should be tightened evenly and grounded may be completed. Sufficient time should be allowed for setting and seasoning of the foundation.

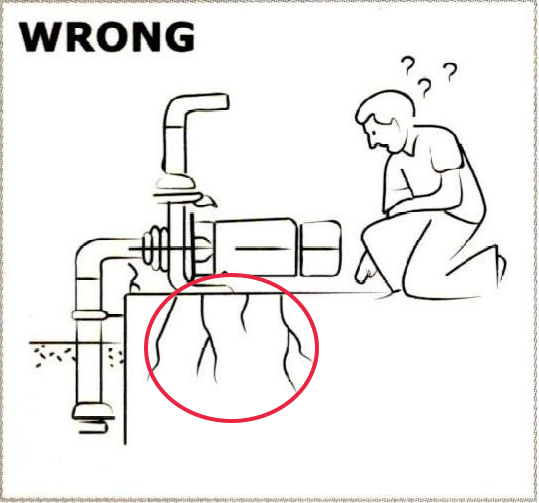

Piping :

Pipe Sizes Should be as per the flange size to get higher discharge. It is not recommended to reduce the pipe size. The Piping Should be Airtight. Any Leakage in Suction Pipe may drastically affect the performance of the pump. The Piping Should as Short as Possible for Getting Better discharge.

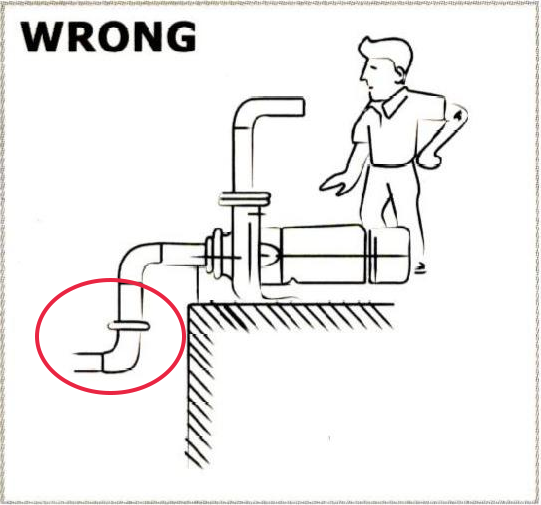

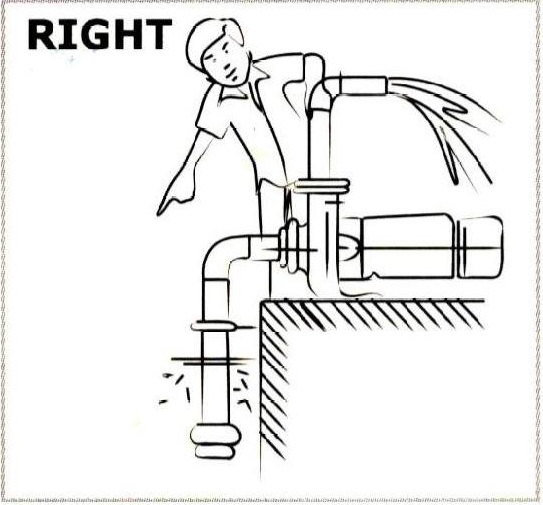

Piping :

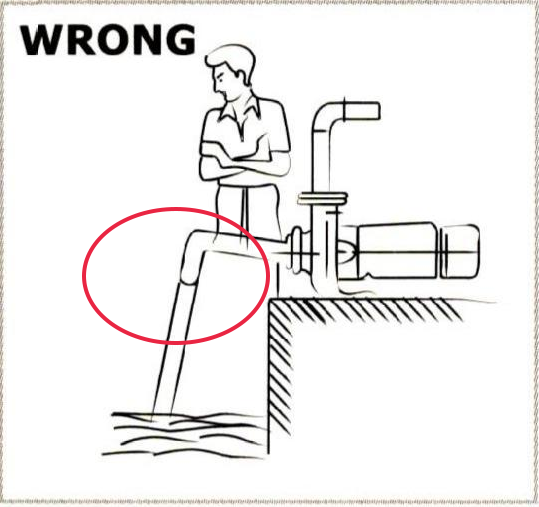

The Horizontal Length of the suction pipe should be straight to avoid air trapping in pipe.

A Check Valve Should be installed in the pipeline for Delivery Pressure more than 20 meters

There should be sufficient clearance around the sucton for good performance.

Electrical Connection :

- Proper earthing connection should be made at the bolts provided for earthing

- Proper size cable should be used between supply and motor terminals to minimize voltage drop.

- Nuts at terminal should be tightened properly.

- No. of Joints in Cable Should be Minimum as Possible, preferably joints should be avoided.

- Wires and connections should be properly insulated. If not, it may lead to fatal shock.

- Proper backup protection (reputed makes starter, main switch and fuse) should be used.

Trouble Shooting :

Problem | Possible Causes | What to do |

|---|---|---|

Motor Fails to start | 1. No power supply 2. Capacitor failed 3. Impeller stuck due to keeping idle for longer time | 1. Check incoming connections. 2. Get it replaced. 3. Rotates the shaft with help of screwdriver (a slot is provided at the shaft end). |

Pump does not deliver water/ insufficient discharge | 1. Pump not primed properly 2. Suction lift too high 3. Too many bends in suction branch. 4. Water level gone down below foot valve/ suction pipe end. 5. Piping is not air tight in suction branch. 6. Air trapping in suction branch. | 1. Reprime the pump. 2. Place pump closer to water level. 3. Reduce number of bends. 4. Submerge the foot valve/pipe end in water. 5. Apply proper sealing at all joints. 6. Horizontal length of suction pipe should be straight. |

Motor starts with humming noise, does not rotate and then trips | Pump Jammed | Switch of the supply and rotate the shaft with help of screwdriver |

Pump set trips after discharge for a while. | Abnormal supply voltage conditions than that specified | Switch off the supply and check supply voltage |

MAINTENANCE :

- Ensure daily or alternate day running of the pump.

- If pump is to be kept idle for a long period, fill it fully with water or any other preservative.

- Periodically clean the strainer to avoid clogging.